LIDAR plays a major role in automotive, as vehicles perform tasks with less and less human supervision and intervention. As a leader in VCSEL, ams is helping to shape this revolution.

LIDAR (Light Detection and Ranging) is an optical sensing technology that measures the distance to other objects. It is currently known for many diverse applications in industrial, surveying, and aerospace, but is a true enabler for autonomous driving. As the automotive manufacturers continue their push to design and release high-complexity autonomous systems, we likewise develop the technology that will enable this. That is why ams continues to bring our high-power VCSELs to the automotive market and to test the limits on peak power, shorter pulses, and additional scanning features which enable our customers to improve their LIDAR systems.

In 2019, ams together with ZF and Ibeo announced a hybrid solution called True Solid State where, like flash technology, no moving parts are needed to capture the full scene around the vehicle. By sequentially powering a portion of the laser, a scanning pattern can be generated, combining the advantages of flash and scan systems.

Making sense of the LIDAR landscape

At ams, we classify LIDAR systems on seven elements: ranging principle, wavelength, beam steering principle, emitter technology and layout, and receiver technology and layout. Here we discuss the first five.

The most dominant implementation to measure distance (ranging) is Direct Time of Flight (DTOF): a short (few nanoseconds) laser pulse is emitted, reflected by an object and returned to a receiver. The time difference between sending and receiving can be converted into a distance measurement. Moreover, with duty cycles of <1% this system takes thousands of distance measurements per second. The laser pulse is typically in the 850-940nm rage, components are readily available and most affordable. However, systems can also be using 1300 or 1550nm, the big advantage is eye safety regulations allow more energy to be used here, and in theory, this provides more range. The downside is that components are expensive.

To scan the complete surroundings (or field of view) of a vehicle, the system needs to be able to shoot pulses in all directions. This is the beam steering principle. Classical systems used rotating sensor heads and mirrors to scan the field of view section by section. As these systems are bulky, they are being replaced by static systems with internal moving mirrors. MEMS mirrors are also about to enter the market. Another approach is flash, where no moving parts are needed at all. The light source illuminates the complete field of view, and the sensor captures that same field in a single frame like a photo. As the full scene is illuminated, and to remain eye safe, this means the range must be limited.

On the emitter side, edge emitters continue to be frequently used, based on earlier developments. They have a high-power density, making them suitable in combination with MEMS mirrors. Where first iterations were single emitters, meanwhile 2-4-8-16 emitters are being integrated in a single bar. Fiber lasers are another interesting technology. They offer even higher power density, and typically are used in 1550nm wavelength and come typically as a single emitter source.

ams is a leading supplier in the VCSEL emitter technology. Our high power VCSELs can differentiate in scan and flash applications as they are very stable over temperature, are less sensitive to individual emitter failures, and are easy to integrate. However, the best characteristic of VCSELs are their ability to form emitter arrays. This makes VCSELs easy to scale. It also allows for addressability, or powering selective zones of the die. This enables True Solid State topology, which we consider to be the most all-rounded LIDAR solution.

LIDAR enables Autonomous Driving

The most commonly accepted way to classify vehicles on their level of autonomy is by the definitions of the Society of Automotive Engineers (SAE). At SAE Level 3 and above, the vehicle takes over responsibility from the driver and assistance turns into autonomy. This means the vehicle should be able to perform its task without human supervision and intervention. This requires a step function in required system performance. Where Level 1 and Level 2 vehicles assist the driver and typically rely on camera or radar, or a combination, there are shortcomings in these technologies for 3D object detection. LIDAR technology addresses this, and there is wide consensus in the industry that from Level 3 onwards, LIDAR is needed for 3D object detection.

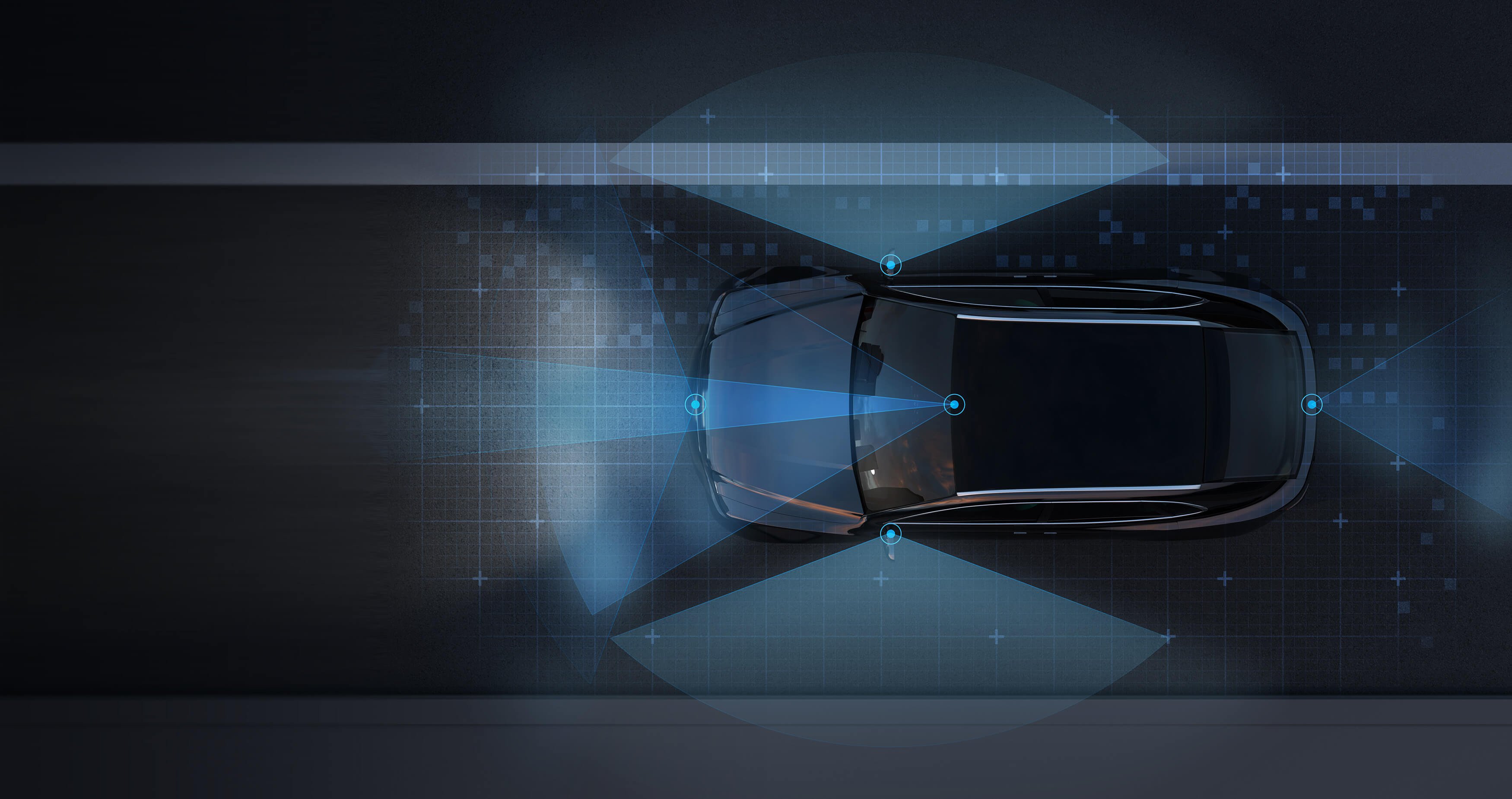

When 3D LIDAR is combined or fused with camera and radar, a high-resolution map of the vehicle’s surroundings can be constructed and allow the vehicle to safely fulfil its mission. The automotive industry started with more straightforward driver-assist use cases used in Level 1 and Level 2. As sensors and data processing gets more advanced, further more difficult use cases can be covered, such as Highway Pilot or City Pilot.

Ultimately, when every conceivable use case can be fulfilled by the system we define this as a Level 5 vehicle – fully autonomous and the holy grail of autonomous driving. This is expected to still be quite a number of years out from today. Moreover, there will be huge pressure to bring down cost and rationalize content per vehicle – to make autonomous driving available to the mass market.

Interested to learn more?

Let us know if you would like to discuss how you could be using ams technology to support your potential LIDAR applications!

Contact ams sensor experts